The NeedleBar

Bobbin Winder Types

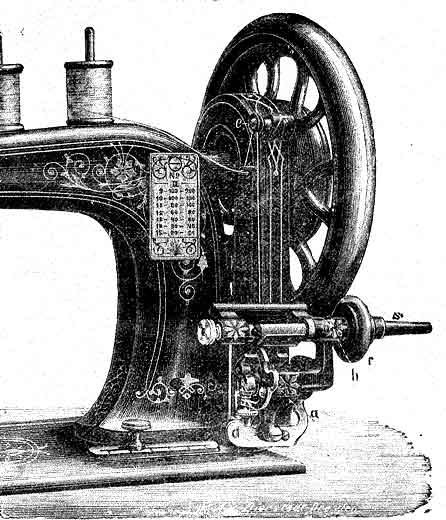

Seidel & Naumann Transverse Shuttle

Courtesy of Claire Sherwell

PATENT AUTOMATIC

DOUBLE ACTION BOBBIN-WINDER

HAVING placed the reel on one of the spindles, on the top of the arm of the machine, pass the cotton upwards through the wire eyelet (by simply slipping it into it from the back) then over and between the tension discs (c), down towards the winder from behind and under its shoulder-bar towards yourself.

Now, take the bobbin in your right hand, and having threaded the cotton through the little hole in one of its brass ends, place the bobbin in the winder by fitting the little hole through which you have just passed the cotton into the corresponding pin in the right-hand socket of the winder, then place the other side of the bobbin in its position within the left-hand socket, to do which you require to draw out the left piston-button, until you candrop the bobbin into the left-hand socket.

Having now the bobbin properly threaded in its position, press the little lever (a) under the thread pressure plate, which will cause the latter to spring flat against the bobbin; a second pressure against (b) will bring hte India rubber ring in contact with the fly wheel.

Disconnect the fly wheel and put it in motion and the bobbin will begin to fill and will throw itself out of action when full. Should the winder be thrown out of action before the bobbin is full enough, or only when the bobbin is too full, the defect either way can be regulated by means of the screw (f) on the lever (d).

It is advisable to regulate the screw (f) so, that the bobbin is not allowed to wind too full, otherwise it is apt to jam in the shuttle.

Should the bobbin be only required to be partly filled, the winder can be thrown out of action by simply pressing on the little lever (d) at the bottom of the left-hand side.

Should the India rubber wheel touch the fly wheel too firmly or not firmly enough, the slightest turn of the screw under the winder and facing the operator, will regulate a proper tension between the two wheels.

© Alan Quinn 2000

This web site may not be reproduced or distributed in part or in whole without the prior written permission of the author