The NeedleBar

Bobbin Winder Types

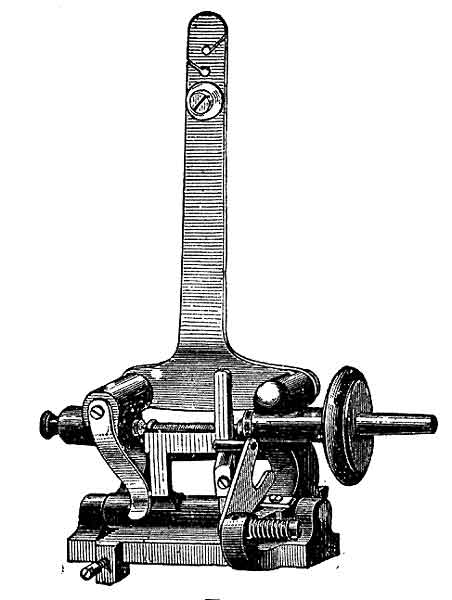

Frister and Rossmann Transverse Shuttle (1901 - 1914)

Courtesy of Claire Sherwell

TO WIND THE BOBBIN

Place the reel on the spindle, nearest the wheel; pass the cotton as it comes from the reel through the top slip of the perpendicular steel bar, between the tension discs, into the lower slit, and continue the cotton down the back of the steel bar.

Now detach the steel bar by pressing it towards the flywheel, and pass the cotton underneath from the back; replace the steel bar, thread the cotton through the hole in the bobbin from the inside, then put the bobbin in the winder, so that the small hole on one end of the bobbin fits into the corresponding little pin on the right hand bobbin-holder; and draw out the thumb-screw on the left-hand side sufficiently to allow the other point of the bobbin to drop into its place.

Now press the spring gently against the bobbin, and press the perpendicular steel bar sufficiently towards the machine fot the india-rubber ring to touch the fly-wheel, and proceed to wind the bobbin by turning the handle of the machine.

Should the india-rubber ring not grip the wheel tightly, see that the screw which fastens the winder to the bed-plate is driven well home, and then adjust by means of the small screw which will be seen at the bottom of Fig. 4 at the left.

© Alan Quinn 2000

This web site may not be reproduced or distributed in part or in whole without the prior written permission of the author