THE NEEDLEBAR

Manuals Section

I N S T R U C T I O N S

For operating and adjusting the

REGAL PAVEWAY

ELECTRIC SEWING MACHINE

Part Two

TO REGULATE THE TENSION

Lower Thread

For most all ordinary work this does not

require changing, the stitch being governed by the upper thread. If the shuttle

thread draws easily and smoothly, but with a firm feeling, it is probably right,

and the stitch should be perfected by the upper tension. The shuttle tension

is obtained by means of the screw near the point of the shuttle. Turn it to

the right to increase, and to the left to diminish the pressure of the thread.

The change can be accomplished without removing the shuttle from its carrier.

TO REGULATE THE TENSION

Upper Thread

Turn the tension thumb screw to the right until the thread seems

to draw through with about the same resistance as it did from the shuttle, for

the purpose of making a stitch alike on both sides.

If the under thread lies straight or is drawn sufficiently into

the goods, turn the tension screw more to the right. If such is the case with

the upper thread, turn to the left, or increase the shuttle tension. Soft or

thin goods require but little tension, but on thick and heavy goods the tension

should be heavier.

Note - Too little tension will make looped stitches.

Proper adjustment of the tension is one of the most important

requisites for neat stitching.

Loop stitches sometimes occur from using needles too fine for

the thread; but generally from the thread feeding off too freely which is corrected

by increasing the tension. If the upper thread loops, increase the upper tension;

if the lower, increase the shuttle tension.

If you have too much tension on both threads it will be shown

by the constant breaking of the upper thread or the gathering of the work.

If you wish to sew with a view to ravel easily, leave the upper

tension so light that the under thread will not be drawn into the goods, but

lie straight.

For sewing flannel or "bias" seams, use a fine stitch

and as light a tension as possible so as to leave the thread loose enough to

stand the strain of stretching the goods.

BREAKING THE UPPER THREAD

May be caused by the needle not being properly set, the machine

not threaded correctly, the upper tension too tight, the thread uneven and the

needle too small for it, the eye of the needle being too sharp, the presser

foot attached to the machine so that the needle rubs against it, or by a sharp

place or burr being formed on the needle plate around the needle hole, by needles

being allowed to strike it.

Breaking of thread is also caused through using a needle of

improper dimension; one not made for this machine, or through the upright part

of the shuttle carrier spring breaking or working loose and catching the upper

thread as it loops around the shuttle.

BREAKING THE LOWER THREAD

May be caused by too much tension in the shuttle, by the bobbin

being wound too full so that the thread at the end slips over the bobbin in

the shuttle, by the thread being caught in the shuttle slide plates or by a

burr formed in needle plate hole through the needle striking it. The shuttle

slides should always be kept tightly closed when operating the machine, the

bobbin should never be wound so full as to prevent its being turned freely in

the shuttle.

|

TO WIND BOBBINS

|

|

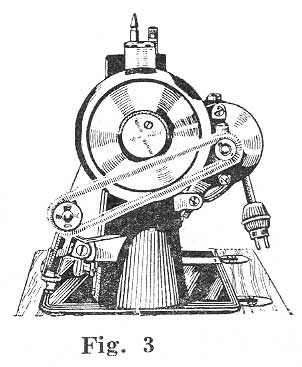

To wind bobbins, raise the spooler to its highest point where it is

locked in position, as shown in Fig.3. Connect spooler pulley and motor

pulley with spring belt, as shown in Fig.3.

Take the bobbin in left hand and the thread in the right. Place the

left hand center of the bobbin in the little depression for it in the

end of the spooler spindle, and by pressing to the left the spindle

will move back and allow the head of the bobbin to enter the friction

cavity or cup at the right hand.

As it enters this cavity see that the end of the thread goes with it,

and that it is held in the cup by the pressure of the bobbin head. This

will hold the thread securely when the winder starts. Unless this is

done, it will be necessary to wrap the thread several times around the

shank of the bobbin or else tie it, in order to get it started. Draw

the thread in the notch at the top of the distributing bar, then down

under the notch at the lower end of the distributing bar.

Loosen the hand wheel by turning milled edge hand nut on right end

of shaft to the left (top toward you) one-half turn, this will permit

the operation of the wheel and bobbin winder while the working parts

of the machine stand still.

|

|

OILING THE MACHINE

There is nothing more important to insure satisfactory working

of the machine than to keep it thoroughly clean and well oiled. Use nothing

but the best quality oil Turn the machine slowly as the oil is put on, to distribute

it in the bearings. Always clean the machine well before putting on fresh oil.

The places for oiling are marked O (See Fig.1). Oil as often as there

is any indication of dryness. If the machine runs hard it is a sure indication

that oil is needed.

MOTOR LESSON

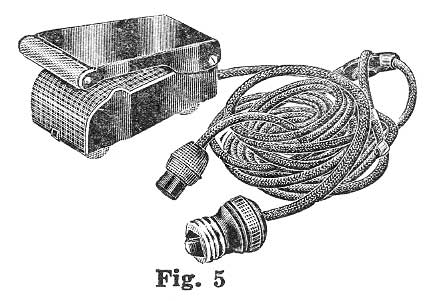

Attach screw plug at end of the long cord, as seen in Fig. 5,

to any electric light socket. The short wire makes the motor connection. Place

the foot control on the floor and press lightly, this will start the wheel moving

slowly, pressing a little harder will make it run faster.

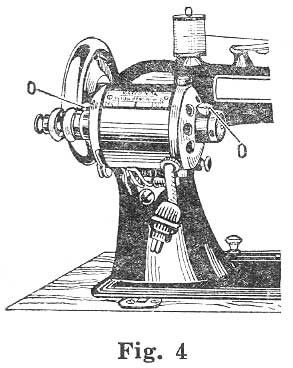

Points marked "oil" in Fig. 4 are the only places

where the motor requires oiling. A drop of good sewing machine oil once a day

where a machine is used constantly by dressmakers, or once a week where it is

used occasionally, as in a home, will insure perfect running and satisfactory

results.

Part One

Back to Online Manuals Index

| To Main Index