Every machine warranted to sew well, and guaranteed for twelve months from date of purchase

Does not require taking to pieces to oil or clean. Easy to work and to manage. With proper use will run for years without requiring any repairs or outlay whatever.

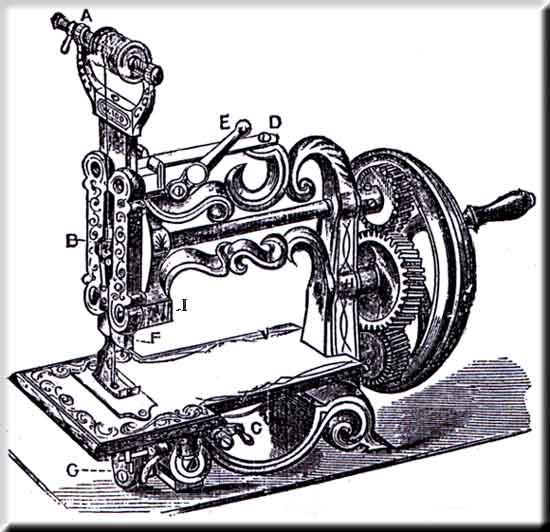

| A. Tension Nuts | F. Needle Screw |

| B. Cramp Post | G. Crank and Feed Cam |

| C. Screw to regulate the Length of Stitch | H. Standard |

| D. To adjust Pressure of Feet | I. Place to fix Quilting Guide. |

| E. Lever raising the Presser, so as to put under the Work |

Through the great success which the genuine Raymond's Machine has achieved, numerous worthless imitations are now offered, against which purchasers are cautioned. No Machine is genuine unless stamped with the nam: CHS. RAYMOND and date of U.S. patent on the needle plate.

-------------------------------------------

NEEDLES CONSTANTLY ON HAND, and may be sent by post.

Price 2d each and Postage

--------------------------------------------

EXPERIENCE proves that all persons, when first commencing to use a Sewing Machine, no matter how much merit it has, will meet with more or less difficulty in applying it to different kinds of work successfully. The following directions are designed to aid beginners, and must recieve their strict attention.

Take off the tension nuts, spring and cone, put the spool on so as to roll toward the front plate. Put on the outside cone with thetapering part part in th hole of the spool, the wire spring against the cone, and screw the nuts up till the tension is right. (By tension is meant the hardness with which the thread rolls from the spool. To put on more tension is to make the spool go harder by screwing the nuts tighter against it, less tension making it go easier by turning them back.) The outside nut is to hold the other from turning, and it is positively necessary to have it turned tight against it.

Push the lever E (see cut) towards the spool till it stands up straight, put under the work and push back the lever, letting down the presser. Put the thread through the eye in the front plate: thread the needle through the front, wind the thread once round the cramp post B in the needle bar, bringing it to where it is double on the side next to the cramping roll, and the machine is ready for operation.

Can be made longer by turning the screw C in (to the right); shorter by turning it out (to the left). By screwing it out too far, the feed will stand still, and will not move the work at all; the machine will not sew. It must in this case be turned in again until the the work does move, but care should also be used not to screw it in too far for making a long stitch, as it will jam the feed, making a clicking noise, and may twist the parts from their proper places.

Grasp the machine around the standard H, with the fingers resting on the wheel to keep it from turning. Loosen the screw F in the needlebar and draw the needle down, out of the bar, then out at the side. To insert the new needle, push it down first through the hole in the steel plate, then up into the hole of the needlebar, as far up as it will go, bring the long groove and eye of the needle directly in front and tighten the screw F again, to keep it in place. Examine very closely, and see that it comes in its proper place, spring it with the fingers until it comes to the required point. It should come just as near the hook as possible, and not crowd it; let the point come close to the lip of the hook, but don't let it rub against it. The needles are numbered, and should be used according to size.

No. 0, for thread from 90 to 150.. .)...............................-

No. 1, for thread from 60 to 100...)----------------------------

No. 2, for thread from 50 to 70.... ) ------- Brook's Cotton

No. 3, for thread from 30 to 60.... )-----------------------------

No. 4, for thread from 24 to 40.... )-----------------------------

Raise the needle to its highest point, cut off the thread near to the material, and draw the work straight from you, out of the machine. This fastening may be may doubly secure by interlooping the end of the thread with the last stitch.

All the parts that have any friction must be kept lightly oiled with the best machine or clock oil. The cut across the needle bar; the pin that sends it up and down, the little cam underneath which oushes up the feed, and the crank which moves the hook plate, should be particularly attended to. Want of oil will wear the machine -- not work. Also keep the machine wiped clean and covered from dust when not in use.

Never loosen the screws in the gear or hand wheel, to oil, clean or any other purpose, as it will throw it out of adjustment, and require an experienced hand again to set it right.

In sewing articles which are liable to wear off the thread, like dress skirts, they should be commenced at the bottom, as the seam will never ravel in the direction sewed. Care should always be taken to fasten the thread at the closing end of the seam. To make good work, the seam must not be sewed too tight. Very tight seams will not stand washing. Let the tension be as light as possible, and draw up a smooth chain underneath.

When good thread breaks in common work, there is too much tension. In close starched goods, it sometimes breaks or cuts off the in going through the cloth, when it will be necessary either to wash before sewing, or rub a little hard soap (like shaving soap) on the place to be sewed. For white calico and print, teh No. 2 needle is the best.

If there is too little tension, it will drop stitches, leave loops, loose ends, and tangle the thread underside -- perhaps not feed at all. Always put on more tension when it does not make a smooth cord underside: but do not move the nuts too much at once -- they require but little turning to change the tension.

To sew delaines and other loose cloth that is not starched, put under the cloth a strip of smooth newspaper, also, to stitch collars, or anything that is desirable to draw the thread tight on the face side, and still have the seam loose, put under several thicknesses and sew through the whole, after which pull off the paper, and it will leave the work very nice.

For fine work use the best glazed thread -- unglazed is better for coarse. No uneven thread will work at all. Finer cotton is necessary for Sewing Machines than for Hand-sewing; it will make a neater seam, and stand washing equally well as coarser cotton. Spool silks, or others, wound on cotton spools can be used.

When the the machine is taken to begin work, look it through to see if the tension, the size and position of the needle and work are right, according to the foregoing directions, and there will be no trouble. Every machine has been thouroughly tried by at least two persons, and been found without defect, before it is sent out.

If difficulties present themselves at first, Ladies will therefore kindly attribute them to theri inexperience, and not to any fault of the machine. Remember, the directions are for use, and must be followed to do the work successfully.

In every needle there are two grooves, a long one on one side and a short one on the other. It is essential that the needle be inserted in the right way, with the long groove and the eye of the needle straight in front. If the short groove is put in front, or if the groove is placed sideways, the machine will miss stitches.

Other reasons for missing stitches may be the following:

If a bent or blunt needle is used.

If the needle is not pushed up in the needle-bar as far as it will go up.

If the needle is too coarse for the work, or if a corresponding number of thread for the size of the needle is not used.

If the cotton is either not wound round the cramp-post at all, or in the wrong way, and if there is too little tension.

It is also of consequence that the needles proper and specially made for the machine, stamped with the name "Raymond", should alone be used, as any others will prove but a vexation, not sewing properly, and they may even spoil the mechanism.

Screw it in the place of the tuck-guide. Let the work pass along between the two plates with its edge up against the two projecting pins. The distances at which the two pins are set from the needle gives the width of the tuck.

Screw it in the place of the tuck-guide, and pass the braid between the two claws. Adjust the moveable part of the binder according to the width of the braid, and put the work between it.

Screw it in the place of the tuck guide, with the point right opposite the needle. Pass the raw edge of the material carefully through the hemmer, till it reaches under the needle. Guide the work as usual, holding the edge of the work at the beginning. Then turn a little piece the breadth of the hemmer a second time, put it into the hemmer, keeping it well up to the edge, and it will continue to turn itself.

Fasten in the place of the tuck guide. Turn a little piece the breadth of the hemmer a second time, put it into the hemmer, keeping it well up to the edge, and it will continue to turn itself.

Screw it in the place of the tuck guide, the curved projecting point of the brass to rest against the Needle plate. Place the piece to be frilled under the spring, the piece to be sewn to over the spring and under the presser. Hold the frill loose between the first and second fingers, the piece sewn to between first finger and thumb. Turn the stitch screw for a long stitch, and the tighter the piece sewn to is held between the fore finger and thumb, the fuller will be the frill.

Pass the braid underneath the small piece of wire on the Presser-foot, and draw it through a little past the needle. Put under the garment to be braided, with the desired pattern marked on it, let down the presser and guide the work according to design.

The tuck guide for the self-sewer is used along with the tuck-marker. Place either of them on teh top of the tuck-marker and fasten the two at a desired distence with the tuck guide screw -- the spring of the tuck-marker to go underneath the needle-bar, against the needle. Proceed, as usual, and the needle-bar in descending will carry the spring down with it, which, striking the knife of the tuck-marker, marks the next tuck, while one tuck is sewn.

Screw it (thumbscrew in front) to the part marked "I" on the lower arm of the machine. (See cut). Set the curved rod (another name for the adjustable guage) at the required distance from the needle - the nearer to the needle, the narrower the quilting -- further off, a wider quilt. Bring the point of the guage down as close to the work as convenient. Place the first row of sewing (which has to be guided by the eye) under the guage and proceed. It serves as a guide for the second row, which, in its turn, place under the guage, and so on.

Use No. 4 needle a coarse but even silk, and not too small a stitch. Place the paper pattern on the material and sewing through the paper, guide the work according to the design. The paper caneasily be removed afterwards, and the chain-stitch, on the other side, will show as beautiful embroidery. All kinds of most effective fancy work may be produced in this way.

By turning out the screw, which will be observed at the back of the Pedestal, the Machine will lift out, for the purpose of oiling, cleaning, changing the needle, etc.