THE NEEDLEBAR

Online Manuals Section

INSTRUCTIONS FOR

USING THE

NEW WILLIAMS SEWING

MACHINES

Part Two

INSTRUCTIONS FOR USING THE MACHINE

TO OIL THE MACHINE

(See Cuts on Pages 4, 5 and 6.)

| 1st. - See that Machine is CLEAN, then oil in all the small round HOLES

and wherever there is any friction of the working parts. Oil the working

parts of the STAND as well as the head of the Machine. Use only the best

Sewing Machine Oil. Only a small quantity should be used at a time. |

| 2nd. - The curved side of the RACE against which the Shuttle works should

be oiled at least twice a day when the machine is in constant operation. |

| 3rd. - After the Machine has been oiled, run it (with PRESSER-FOOT up

and SHUTTLE out) for a minute, and then wipe off the superfluous oil. |

| 4th. - If the oil becomes gummed, causing the Machine to run hard, put

a little KEROSENE or ALCOHOL in the OIL-HOLES, run rapidly, wipe clean,

and then oil with Sewing Machine Oil. |

| |

|

TO GET THE MOTION

|

| 1st. - Unthread the NEEDLE; remove the SHUTTLE, and raise the PRESSER-FOOT

by turning the LIFTER-HANDLE from you. |

| 2nd. - Place the feet on the TREADLE, with the instep directly over

the ROD upon which the TREADLE rests. |

| 3rd. - Start the Machine by placing the right hand upon the top of the

BALANCE WHEEL and revolving it from you. |

| 4th. - Place a piece of cloth on the FEED and let the PRESSER-FOOT down,

and practice starting and stopping the Machine until you can do so with

ease. |

| |

|

TO THREAD

THE MACHINE

|

| 1st. - Raise the Needle to the highest point by turning the wheel from

you by hand. |

|

2nd. - Place the SPOOL on Spool-pin and pass the thread

into the slot in the Tension Spring, carrying it to the left under the

point of the flat THREAD-GUIDE, and through the hole in the top of the

NEEDLE-BAR. Pass the thread down behind the CHECK LEVER THREAD-GUIDE

(a bent wire near the lower end of the Face-plate), drawing it towards

you between the Guide and the Face-plate. Next pass it over or into

the hook of the CHECK LEVER, after which, push it back from you, between

the THREAD-GUIDE and Face-plate, thence bring it down to the needle,

and pass it through the eye from left to right, leaving about three

inches extending beyond the needle. See Cut, page 4.

|

Raise the NEEDLE-BAR to its highest point; take hold of the

NEEDLE with the thumb and finger of the left hand, and with the right hand loosen

the NEEDLE-CLAMP by turning the top of the winged NEEDLE-CLAMP NUT toward you

about a turn, not more; then lower the Needle and remove it.

TO SET THE NEEDLE

|

|

|

|

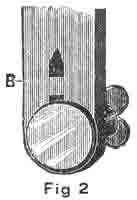

| Now observe the illustration above. Fig. 1 shows the NEEDLE;

A is the shank and B the self-adjusting stop. Fig. 2 shows

the end of NEEDLE BAR and CLAMP, and just above the |

| CLAMP, and in the groove that receives the NEEDLE, is the

stop C, against which the end of stop B (Fig.1) rests, as

clearly shown in Fig.3. Pass the shank of NEEDLE up into the groove of

the NEEDLE-BAR, keeping the shoulder to the right and the long groove

to the left. Guide it up until it rests against and covers the stop C

(Fig.3), then fasten by turning the top of winged THUMB-NET from you.

As the NEEDLE is self-setting, this brings it correctly into place. |

TO WIND A BOBBIN

| Examine the Cut on page 4, and the threading will be better understood. |

| 1st. - Oil the cavity in the end of the SPOOLER-SPINDLE and the bearing

of the SPOOLER-PULLEY before inserting the BOBBIN. |

| 2nd. - At the end of the Upper Shaft, and to the right of the Balance

Wheel, will be found a nut. Turn this nut a little to the left or towards

you; this will loosen the Balance Wheel, so that it will turn freely,

without running the Machine. |

| 3rd. - Put the BELT into the groove in the PULLEY of the WINDER. |

| 4th. - Place the spool of thread on the spindle on the top of arm of

Machine, draw off a few inches of thread, and pass the end of it through

the small hole in brass head of Bobbin from the inside. |

| 5th. - With the left hand pull the SPINDLE to the left and insert the

BOBBIN, taking care to put the little pin in the socket to the right enters

the hole in the end of the BOBBIN. |

| 6th. - Pull the TENSION-PAD towards you until it presses against the

Bobbin. |

| 7th. - Take hold of the thread just above the top of the Tension-Pad,

pass it into the right hand slot in Pad, then round behind into the left

hand slot, then from right to left around the Tension-Screw between the

Tension Discs, then again through the left hand slot, then roll up on

the Spool any slack thread that may remain between Winder and Spool. |

| 8th. - Start the BALANCE WHEEL from you by hand, and proceed as in sewing. |

| 9th. - When done winding, turn the nut to the right, or from you, to

tighten the wheel, and remove the belt from the Winder Pulley. |

(half-page inserted in original manual)

TO WIND THE BOBBIN

|

|

|

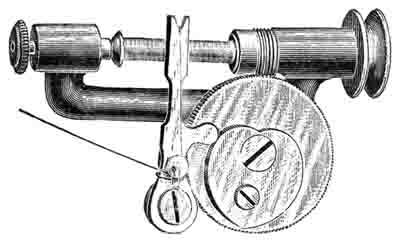

New Style Automatic

Bobbin Winder

|

Oil the cavity in the end of the left spindle in which the bobbin

turns, the bearings and worm at the right end, loosen the balance wheel by turning

the nut towards you which will allow the wheel to turn without the machine running,

put the belt into the groove in the pulley of the winder, then run the machine

before inserting the bobbin on top of the arm of the machine, draw off a few

inches of thread, pass the end of it through the small hole in the brass head

of bobbin from the inside. With the left hand pull the spindle to the left and

insert the bobbin, with the end that you have the thread inserted in to the

left, taking care that the little pin in the driving head enters the hole in

the end of the bobbin, pass the thread into the notch in top of the arm of winder,

downward and into the notch at the bottom of the arm, then round the back of

the tension screw and start slowly to wind the bobbin, holding the free end

of the thread for a few revolutions, so as to get the winding properly started.

There should be no slack thread left between the spool and the bobbin when you

are ready to wind.

TO THREAD THE SHUTTLE

N.B. - Remember the Shuttle is Self-threading.

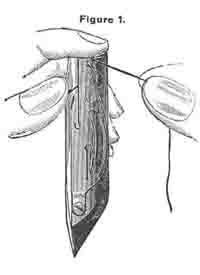

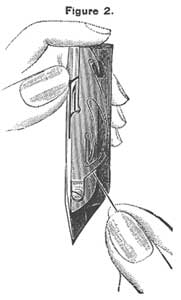

| 1st. - Hold the SHUTTLE between the thumb and middle finger of the left

hand, point down, and spring side towards you. |

| 2nd. - Take the BOBBIN between the thumb and forefinger of the right

hand, holding it so that the thread will draw up and over FROM LEFT TO

RIGHT. |

| 3rd. - Drop the BOBBIN into the SHUTTLE, and press it gently on the

end with the forefinger of the left hand to prevent its turning readily.

Draw the thread into the notch at the end of the spring shown in Fig.

1, continue to draw the thread firmly down towards the point of the SHUTTLE,

and you will find that it will pass under the different points of the

Tension Spring, and finally come into the position shown in Fig. 2. The

SHUTTLE is now threaded and ready for use. |

To increase the tension, turn the screw to the right; to decrease

it, turn to the left. A very small screw-driver is furnished for this purpose.

To put the SHUTTLE in: Have the CARRIER at one end of the race,

and lay the SHUTTLE in the CARRIER, point first, and towards you, the spring

side up. Let the end of the thread (about three inches) lie over the SHUTTLE

and CARRIER, on your right and close the slide.

TO DRAW UP THE SHUTTLE THREAD

See Cut, page 4 - Position of thumb and Thread.

Take hold of the BALANCE WHEEL, with one hand and the Needle-thread

with the other. Let the thread lie slack, so as not to spring the Needle. Move

the Wheel from you once round, and pull up the slack of the needle-thread with

your hand, in order to draw the Shuttle-thread up through the needle-plate;

then take both threads and pass them under the PRESSER-FOOT, towards the back

of the Machine. Then close the slide over the SHUTTLE-RACE.

Part One | Part

Three | Part Four | Part

Five

Back to Main

Index